If you want to know the important aspects of setting up an asbestos enclosure, we have examples from our previous work to illustrate how this happens. There are many key points to get right to become HSE-compliant.

What is an asbestos enclosure?

An enclosure is defined by the HSE as a -

physical barrier employed around the asbestos work area which will contain asbestos dust and waste arising from the work and which will also prevent the spread of asbestos materials to the surrounding environment. It is designed to prevent the spread of airborne fibres and dust and also to prevent the spread of surface contamination during all the activities associated with asbestos removal, including waste handling and bagging, and cleaning.

They are needed to prevent the spread and exposure of asbestos to any other employees that could be affected.

Only specified entry and exit routes must be used (called airlocks). These are used to prevent the spread of contamination and control the movement of people, equipment, and waste in and out of the area.

Asbestos operatives setting up airlocks

When is an asbestos enclosure needed?

An asbestos enclosure is needed for all works whereby you need to hold a license to remove asbestos with the HSE. View our license here HSE LICENSE 04.09.22

These projects include any containing -

- asbestos insulation

- asbestos coatings

- asbestos insulation board (AIB)

- thermal insulation (boiler and pipe insulation, sprayed asbestos)

- AIB ceiling tiles, panels, or boards

How do you actually set up an enclosure to remove asbestos?

The process of setup will vary on the location, type, and quantity of asbestos you need to remove. As a guide, you will need to clearly block off a safe working area and seal all sides to create a tent-like structure.

They can make up parts of existing buildings such as walls, ceilings, and floors. Many people use a timber frame to create an enclosure where there is not already an existing structure to be used. Usually, the structure is built between the floor and ceiling heights.

You should try to keep good visibility to all areas of the enclosure, through the use of vision panels. When this is not achievable, CCTV cameras can be used for any blind spots.

There will be exceptions, such as when the asbestos is at a high-level, or in a difficult position.

You must use 1000-gauge polythene on every enclosure to create a strong, tear-resistant outer layer. Any gaps must be fully sealed and no air can escape.

To prove that your enclosure has integrity, a smoke test is done before works commence. This is where a smoke canister is set off inside the enclosure so that any leaks will be shown with the smoke. These issues must be fixed before any asbestos removal can happen. If any air escapes, this creates a dangerous risk of exposure to any people outside the working enclosure.

The size of the enclosure can vary hugely, depending on the location and amount of asbestos material to be removed. Even if it’s a small working area, an enclosure will need to be built to ensure safe removal.

It should never be bigger than it needs to be.

When the size of the enclosure changes, there are planning aspects that need to be considered. To be an HSE-regulated enclosure, you must use negative pressure units to regulate airflow. These machines (NPUs) bring through clean air to the atmosphere. When the enclosure is larger, more air needs to pass through the enclosure every hour.

This ensures that employees working inside have access to sufficient clean air and the asbestos fibres are regularly filtered. The filter catches any airborne fibres and is treated as contaminated waste and removed accordingly.

When can you remove asbestos without an enclosure?

Although in many instances an enclosure is needed, there are also many that it is not necessary. This usually applies to non-licensed working practices for materials such as -

- asbestos cement materials (corrugated roofing sheets, building panels)

- asbestos floor tiles

This is because the risk is much lower for these materials.

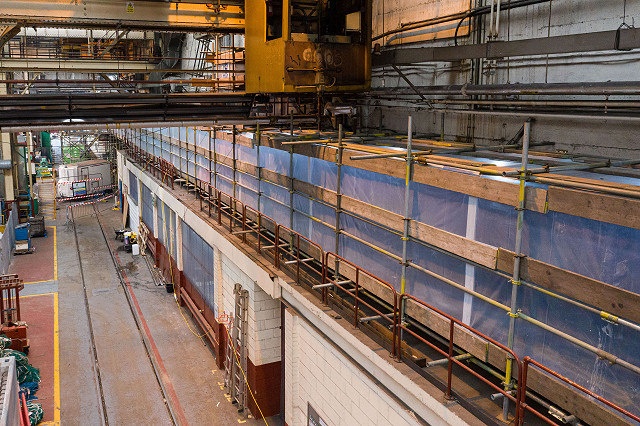

Example of a large-scale asbestos enclosure

Many of our projects have the need for a large enclosure, whereby we remove lots of asbestos material in one go.

This image above shows an area that was built on a fixed scaffold to remove asbestos lagged pipework in a large factory. Read more about this project here.

Another example of a large asbestos enclosure was within a former warehouse due to be demolished. To find out more about this, read this blog post.

Example where you need an asbestos enclosure for a small amount of asbestos loose fill

Although there is only a small amount of asbestos loose-fill located within the penetration hole of a chiller unit, an enclosure must be built for removal.

Summary of asbestos enclosures

In conclusion, asbestos enclosures are needed for licensable materials.

This means that you should never plan to undertake the removal yourself unless you are a licensed contractor like us.

They can come in all shapes and sizes, depending on the specific project.

If you need an asbestos removal project doing, contact us today for a free quotation and action plan.